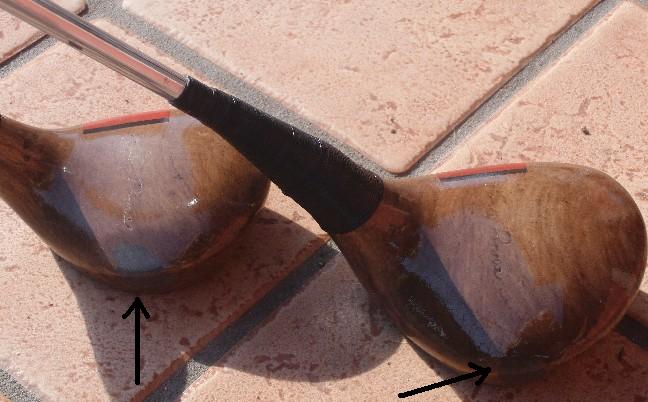

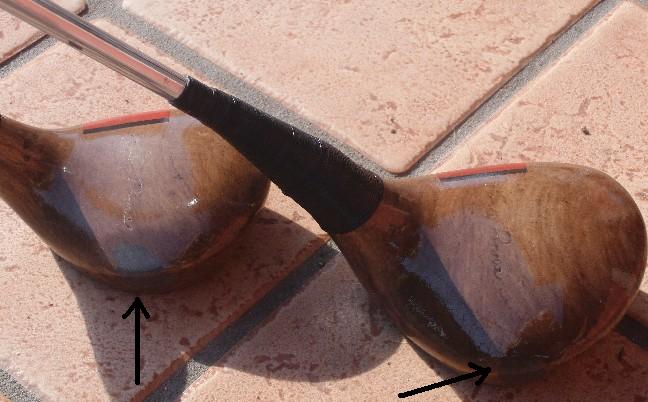

This was the photo that I omitted in the previous post showing where I inserted the swingweights, drilling from the behind the face, although you can’t really see it in this photo.

This was the photo that I omitted in the previous post showing where I inserted the swingweights, drilling from the behind the face, although you can’t really see it in this photo.

Nice work Teddy…they came out great…you are a better man than I am…maybe one day I will try and get to work on an old persimmon again and see if I can remember what to do.

Glad they came out nice- especially after Italia post kept them from you for so long we thought they had gone missing!!

you will love hitting them and have them set up well to help your swing. The sound of hitting persimmon is so much nicer- good luck

Yeah, those look good! I really like that color too.

Please let us know how you hit them.

Cheers. I’ve already hit them a couple of times into my net and they do feel really nice but of course into a net you don’t get much of an idea on ball flight. My net is full of holes so I can’t hit many - my 2nd shot went skipping through and across the garden and jumped over the wall - I hope it didn’t reach the neighbours that are across the other side of the field! ![]()

![]() Well anyway that put a finish to that practice session.

Well anyway that put a finish to that practice session.

Glad you like the colour IoZ. The colour is exactly like all my homemade furniture, which is oak - to save money I just used the same tin and it came out fine - it needed a lot of coats. I wanted it to be dark to better mask the holes I drilled for adding the swingweights, and of course I saved a tiny bit of cash (miser-alert).

Nice one Teddy, Great stuff.

I did have a little chuckle at all your little problems there, cause I have had pretty much all of them and many many more. But it is great fun doing this sort of stuff and it gets a lot easier with practice. Well done!

I managed to get out today and play a short course that has 2 par 5s, 6 par 4s and 10 par 3s giving me 8 opportunites to pull out my new persimmons. I won’t be going back to my light and upright titanium driver and woods anytime soon. ![]()

On the way to the course my son was ribbing me about how he couldn’t wait to see me shank my beautiful new persimmon driver. He was going to log on here and tell you all about it!

I must admit I had no idea whether I’d be able to hit the centre of the face, or get any kind of distance. I was pleasantly surprised. I’ve set them up flat, heavy (about E1 and 14 ounces) with X-stiff shafts (although not tipped) which is beyond anything I’ve ever played before. The recent diagram that Lag posted showing the possible displacement being from slightly left to right was true - I didn’t hit one ball left. A few balls early on in the round escaped right - not so much slices as push fades - shots which would normally be damaging of course although I was lucky to find them and recover. Seeing as I hadn’t played in a number of weeks, I wasn’t too bothered about this. I managed to adjust to this and after a few shots the ball was going straight or with a slight fade, and one slight pull that went straight. What surprised me was that distance-wise, I hit the ball FURTHER than with titanium. ![]() OK, so maybe I don’t hit titanium very far. I measured one 3-wood that was slightly up hill that I hit 230. I know it was further than I normally hit because it was a big dog leg left and normally I hit the 3 wood short of the corner but with the persimmon I hit it through the corner into the rough.

OK, so maybe I don’t hit titanium very far. I measured one 3-wood that was slightly up hill that I hit 230. I know it was further than I normally hit because it was a big dog leg left and normally I hit the 3 wood short of the corner but with the persimmon I hit it through the corner into the rough.

I think the weight of these woods really helps someone like me from over-accelerating. I believe many high-handicappers are penalised when using titanium as they don’t have the natural swing speed to get the benefit out of them. I don’t think I lost any swing speed with these persimmons but I did gain in force and the result was longer distance.

The conclusion was that I loved playing these persimmons and wish I hadn’t waited so long to try it. Now that I’ve tried it I don’t think I’ll be going back. Finally there is the sweet sound that the persimmon makes. It’s hard to describe but it’s like a crunch or a thud, not a ting. I could really feel the shot in my hands and I could feel how the club released through impact.

Despite these persimmons having a smaller surface area on the face, I didn’t mis-hit one shot - something I can’t say for when I play titanium.

Here, one more golfer has joined the persimmon club. ![]()

Teddy–thanks for that post. I absolutely agree. There’s so much more opportunity to go really hard at it playing flat, heavier gear. I love my persimmon driver and though I didn’t really get a chance to use it, got it at the end of last season, can’t wait for spring to arrive.

Great stuff Teddy, If you keep that up it won’t be long before your son wants one of those old school persimmons as well. ![]()

Don’t laugh too hard at this one…It’s my first attempt at flattening a persimmon…It’s a Tommy Armour and have the matching 3-wood too…

Everything was going along smoothly until I tried to re-drill the flatter hole…I’ve got the angle that I’d like (48 degrees) but concerned about the neck of the wood…Should I re-fill with sawdust epoxy and re-drill? or do you think that it doesn’t matter because the whole neck area will get the epoxy sawdust treatment again?..or the ferrule/neck won’t match up a just look cosmetically bad with the finished product?

Also, does the stain just never come totally come out on some woods no matter how much you sand them?

Thanks for everyone’s help in advance,

Mashie

hey Mashie, It doesn’t look bad at all to me!

The part of the neck that is damaged will be covered up with a mixture of sawdust and epoxy anyway to get rid of the gooseneck look that is caused by the flattening. See pic below:

Also, getting the finish sanded off can be a pain in the @$$ and it’s up to you to decide if it’s worth the hassle. You will lose some weight due to the sanding obviously, but you should be able to get it all off and up the weight with some lead.

Good luck!

Thanks IOZ…

I’ll go ahead and epoxy it up then…The lie and square face after the shim look good to me…

I’m going to stain it with a dark deep color either in the red family or black again so I’m not that concerned about the remaining stain…

No problem Mashie72,

One more thing; make sure that after sanding, the top of the insert sits flush with the wood behind it. If it’s sticking out (even just a bit), chances are that the forces of impact will put a skymark-like crack in the finish of the club.

Hope this all makes some sense. . . . .

Good luck with the refinish.

IOZ77

That assumes I can find the center of the clubface ![]()

Thanks a bunch & it does makes sense…

A while back I read that Wood Bros soaked their persimmon in linseed oil to condition the wood and increase the weight.

Just wondering if anyone has ever tried anything like this once the finish was sanded off their persimmon?

Seems like once you get down to the bare old wood it might like some sort of spa treatment before being sealed back up again.

Here is a link to the post on Golfwrx by “freddiec”.

golfwrx.com/forums/topic/317 … -and-more/

Hey, NRG whatever became of that block of wood you got on Ebay??

Dani, I asked Freddie this very thing a while ago and he said he was going to ask Dave Wood when he got a chance. I haven’t heard back from on that yet.

From what I understand, the old “Oil Hardened” persimmons would be soaked in linseed or similar oil for 6 to 8 months.

Yummy, they look delicious.

Thanks for the pics very interesting, to me.

I love wood ![]()

OT, but let me explain;

When I was a kid my father owned a lumber yard and custom mill shop. He always smelled like fresh saw dust when he got home, I still love that smell. Anyway, I was an only child and on the weekends he would drag me with him and he (we) would go look at all things wood (like ornate old hand carved bars made from exotic woods or arched garage doors that were formed and stained to perfection). He instilled in me an appreciation for the material and it’s beauty… then he would buy me an ice cream and take me home. Life was good.

Dani,

I’ve not really done much with that club yet.

I still need to find someone to supply me with 2.5mm thick brass for the soleplate. I found a local company who sells it but the guy wanted £20 for a tiny piece of brass like that, so I told him to stick it. I tried filing down a soleplate from an old club to remove the makers stamp, but that reduced the thickness and weight too much.

I contacted Dave Wood and he kindly offered some advice on the material used for the insert (vulcanized paper fiber). I found a supplier in China who does that stuff, but the minimum order is 300 tonnes.

It might take a while to finish that club.

There was a SWEET Lot of inserts, screws and asst clubmaking parts, all out of the Macgregor factory that Persimmonpal snapped up last year. I can’t remember if there were any blank soleplates but there were a bunch of all the different insert styles. All the original good fiber ones, some with the brass centers too plus the brass screws that nobody makes anymore. He very kindly offered me my pick of the litter at the time, try sending him an email if you do want to finish it up. In the meantime you can start soaking and sanding it down, should be ready before Xmas…