IOZ,

You are touching on a subject very close to my heart, as I spent 13 years as a fishing rod designer. The spine in a tubular structure is a very misunderstood thing. Most if not all folks are under the impression that spine is a “thing” caused by a single manufacturing anomolie. In a graphite golf shaft or fishing rod, most think that it’s cause by the overlap of the fabric. For the record, the spine is an “effect” not a “thing” that is caused by about 8 different factors, namely, fabric overlap, ovality, eccentrity, voids in the resin, inconsistencies in the fabric, fabric alignment, straightness of the structure itself etc…add all these together when a tubular shaft is under a load, and you get the spine. The spine is an effect caused by the AVERAGE of all these forces when the structure is under a load. Additionally, ALL tubular structures have a spine, PVC pipe, tree branches, golf shafts, fishing rod blanks…they all have a spine.

Now, regarding a fishing rod, here is where things get VERY confusing for most folks. There was a long held belief that when building a fishing rod that the spine MUST be placed in a certain orientation to prevent the rod from twisting under a load (a big fish hopefully). The spine always seeks to twist to the outside of a loaded structure. If you take a fishing rod and bend it, the rod will twist so that the spine is on the OUTSIDE of the curve…if you do this, you can feel, and see it “snap” into place. For 50 years, everyone thought a rod would twist under a load if the spine wasn’t oriented correctly. While in theory this sounds great, it is HORRIBLY incorrect…everyone forgets that a fishing rod has guides that are attached to the rod blank, that funnel the fishing line down the length of the rod. The fact is that it is the orientation of the guides and the pressure of the line on those guides under a load, that what will cause or not cause the rod to twist. Here’s why; on a casting rod, the reel, guides and line are on top and the line runs down the top of the rod…in this case the rod will want to twist no matter where the spine is placed, because the forces on the blank are being exerted from the line being on top…and the line is seeking the path of least resistance, which is the bottom of the rod, so the rod wants to twist. And, the higher the guides sit off the top of the blank, the more the rod wants to twist. This is why the last 10 years, the rod industry has moved towards smaller, more low profile guides on casting rods, because it reduces weight, and helps reduce torque from the line on the guides.

Conversely, on a spinning rod (or flyrod), because the reel, guides AND LINE are already on the bottom of the rod, they are already in the most stable position, so a spinning rod will NEVER twist no matter where the spine is placed.

On ANY fishing rod, the torque caused by the pressure of the line on the guides is what causes the structure to twist…not the spine. The force created by the line on the guides ALWAYS negates the forces of the spine. If we fished with rods that had no fishing line and no guides, then yes…the spine would be the cause of the twist, but since we have to have fishing line, and guides to funnel the line down the rod blank, and under a load, that line will always exert pressure on the guides,then the spine has very little importance…at least regarding rod twist.

I got into an heated discussion with a rod builder at a trade show one time that insisted that UNLESS THE SPINE WAS PLACED ON THE TOP OF THE ROD, THE ROD WOULD TWIST NO MATTER WHAT. I simply asked him if he owned any spinning rods, to which he replied “yes…of course” I then asked him when the last time was that he caught a large Bass was, to which he replied “about a month ago…8 pounder”. Then I asked him “while you were fighting the fish, did the rod suddenly twist in your hand so that it was now upside down with the reel was now on top?” He just laughed and said “ok…I see your point” The ironic thing is that there a re a lot of people that believe this will happen…it just can’t, because the torque created from the line on the guides outweighs any tendency for the spine to come into play.

Now, that’s not to say that one should not orient the spine in a specific location, because the spine effect can and does effect the feel of a rod during casting and fighting a fish. Additionally carbon fiber is always stronger in elongation than in compression, so there is some evidence that acertain spine placement may reduce breakage. But there is much more engineering that goes into a tubular structure that can reduce or resist failure than the spine, most importantly hoop strength, and the material and manner in which one achieves hoop strength. And regarding you’re comments regarding some of your shafts having a less pronounced spine than others…absolutely VERY common. Having a tubular structures with very little to no spine effect is an indication of a very well manufactured structure. It is an indication that they took care to minimize the anomolies that cause spine (straightness, ovality, eccentrity, fabric anomolies etc…). Gary Loomis of Loomis composites told me one time that the thing that seperated them from EVERYONE else was NOT the graphite fiber they were using. It was the fact that they had machinery that allowed them to make a much more precise structure, thereby maximizing the potential performance of the material itself.

Nowdays, when I teach someone to build a fishing rod, I just tell them to put the guides on the straightest axis, rather than the spine. Because if you’re building a casting rod (reel on top), there will always be a slight tendency to twist, and on a spinning rod or fly-rod (reel on bottom), the rod will ALWAYS be stable and never twist.

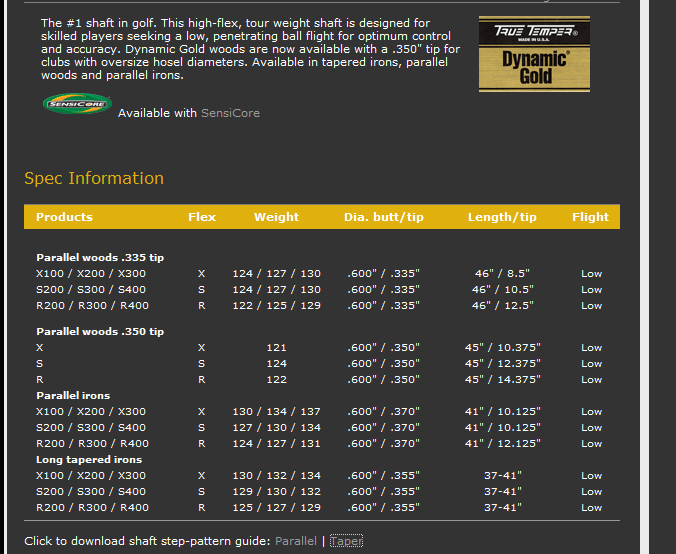

Golf shafts are a whole 'nuther story, because they are subjected to a whole different set of forces than a fishing rod. Additionally, in golf shaft contruction, one can utilize filament winding, which in many cases produces a more efficient structure than the standard “flag wrap” used in fishing rod manufacture. I would say, that in a golf club, utilizing steel shafts…especially stiff or x-stiff, you’re probably not going to notice much if any difference in spine placement…that’s assuming you can even find the spine on a stiff or x-stiff shaft. For all their claims of reduced weight and enhanced distance, graphite shafts are more prone to strange effects because of the higher chance of manufacturing anomolies. Here at ABS, we don’t really care about such things now do we?  I actually heard David Toms say once that when he found a graphite shaft he liked, he never got rid of that one exact particular shaft. The reason is because you can take 50 graphite shafts of the same make model and material and resin and they will likely all feel subtly different. It wasn’t as he said “like a Dynamic Gold X-100 where you always know what you’re gonna get everytime”

I actually heard David Toms say once that when he found a graphite shaft he liked, he never got rid of that one exact particular shaft. The reason is because you can take 50 graphite shafts of the same make model and material and resin and they will likely all feel subtly different. It wasn’t as he said “like a Dynamic Gold X-100 where you always know what you’re gonna get everytime”

If anyone is really interested in this type of stuff, Greg Donaldson, who is the plant manager at Aldila Composites used to be a business aquaintence of mine. I’d be happy to try and engage him in this discussion if anyone is interested.

By the way, which factory were they touring? I have seen one where they tour the St. Croix factory, and one where they tour the Thomas & Thomas Flyrod Factory. I was good friends with the blank engineers at both companies…having said that, St. Croix really has a state of the art facility, and is probably making the best domestically made fishing rod…which sadly is a dying breed just like the domestically made golf club.

Best Regards,

Andy